हमें कॉल करें

08045800958

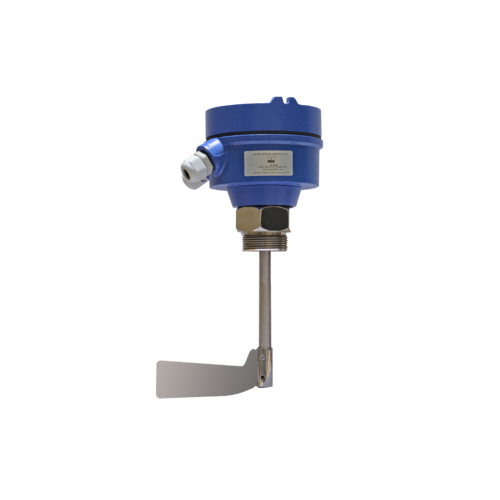

Float Level Switch

270 आईएनआर/टुकड़ा

उत्पाद विवरण:

- रेटेड वोल्टेज वोल्ट (V)

- तापमान सीमा सेल्सियस (oC)

- सुरक्षा स्तर IP65

- मटेरियल Plastic

- साइज Standard

- Click to view more

X

फ्लोट लेवल स्विच मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

- टुकड़ा/टुकड़े

फ्लोट लेवल स्विच उत्पाद की विशेषताएं

- सेल्सियस (oC)

- वोल्ट (V)

- IP65

- Standard

- Plastic

फ्लोट लेवल स्विच व्यापार सूचना

- 10 प्रति सप्ताह

- 1 हफ़्ता

उत्पाद विवरण

A float level switch is a device used for liquid level sensing and control. It operates based on the principle of buoyancy. The switch typically consists of a buoyant float that rises and falls with the liquid level. As the liquid level changes, the float moves with it, activating or deactivating a switch based on the predefined setpoints.

Here's how a typical float level switch works:

1. Float Mechanism: The float is often made of a buoyant material such as foam or plastic. It is attached to a lever or rod that moves with the rise and fall of the liquid level.

2. Switch Mechanism: The switch is connected to the float mechanism. It can be a mechanical switch or a more modern electronic switch, depending on the design of the float level switch. The switch is positioned at a certain height on the float mechanism, and it is activated or deactivated as the float reaches specific levels.

3. Mounting: The float level switch is usually mounted inside a tank or container at the desired level where you want to monitor the liquid.

4. Wiring: In the case of electronic float level switches, there will be wiring connected to the switch that can be integrated into a control system or used to trigger alarms or other actions based on the liquid level.

Applications of Float Level Switches:

1. Pump Control: Float level switches are commonly used in pump control systems to ensure that pumps are activated when the liquid level is too high and deactivated when it's too low.

2. Tank Level Monitoring: They are used in tanks to monitor and control the level of liquids, preventing overflows or low-level issues.

3. Alarm Systems: Float level switches are also employed in alarm systems to alert operators or control systems when a certain liquid level is reached.

4. Industrial Processes: Float level switches find applications in various industrial processes where liquid levels need to be monitored and controlled.

Float Level Switch Specifications:

1. Standard Range: 100 mm to 3000 mm

2. Temperature: Up to 150 degree centigrade

3. Pressure: Up to 15Kg/Cm

4. MOC: SS 304, SS 316, SS 316L, PP, PVDF

5. Connection: Flange End /Screwed Or To Mention

Applications of Float Level Switch:

1. Pump Control: Float level switches are widely used in pump control systems to regulate the operation of pumps based on liquid levels. They ensure that pumps are activated when the liquid reaches a certain level, preventing overflow or dry running.

2. Tank Level Monitoring: Float level switches are employed in tanks to monitor and control liquid levels. This is crucial in industries such as water treatment, chemical processing, and storage facilities where maintaining precise levels is necessary for operational efficiency and safety.

3. Sump Pump Systems: In residential and commercial buildings, float level switches are often used in sump pump systems to prevent flooding. The switch activates the pump when the water level in a sump pit rises, helping to keep basements and other areas dry.

4. Oil and Gas Industry: Float level switches are utilized in oil and gas storage tanks to monitor the level of liquids. They play a role in preventing overfilling and ensuring the safe and efficient storage of petroleum products.

5. Wastewater Treatment: Float level switches are essential in wastewater treatment plants to control the levels of sewage and other liquids in various stages of the treatment process. They help optimize the flow of liquids through different treatment phases.

6. Cooling Systems: In cooling towers and other cooling systems, float level switches are used to maintain the proper water level. They ensure that the cooling process is effective and that equipment is not damaged due to inadequate water levels.

7. HVAC Systems: Float level switches can be integrated into heating, ventilation, and air conditioning (HVAC) systems to monitor and control water levels in humidifiers, boilers, and other components.

8. Food and Beverage Industry: Float level switches find application in the food and beverage industry for monitoring liquid levels in tanks and containers during various stages of production and processing.

9. Marine Applications: Float level switches are used in marine environments to monitor water levels in bilge pumps, ensuring that water is efficiently removed from the boat to prevent flooding.

10. Chemical Processing: In chemical plants, float level switches are employed to control liquid levels in storage tanks and vessels, helping to prevent spills and ensure the safe handling of chemicals.

Float Level Switch FAQ:

Q. What is a float level switch?

Ans: A float level switch is a device used for liquid level sensing and control. It typically consists of a buoyant float that moves with the liquid level and activates or deactivates a switch based on predefined setpoints.

Q. How does a float level switch work?

Ans: The float level switch operates based on the principle of buoyancy. As the liquid level changes, the buoyant float rises or falls, moving a connected switch. This switch is then used to control various processes, alarms, or equipment, depending on the application.

Q. What are the different types of float level switches?

Ans: Float level switches come in various types, including mechanical switches with simple lever mechanisms and electronic switches with sensors. Mechanical switches are typically more straightforward, while electronic switches offer additional features and precision.

Q. What are the common applications of float level switches?

Ans: Float level switches are used in applications such as pump control, tank level monitoring, sump pump systems, oil and gas storage, wastewater treatment, cooling systems, HVAC systems, the food and beverage industry, marine applications, and chemical processing.

Q. Are there different mounting options for float level switches?

Ans: Yes, float level switches can be top-mounted, side-mounted, or bottom-mounted in a tank or container, depending on the specific requirements of the application.

Q. Can float level switches be used for both high and low-level sensing?

Ans: Yes, float level switches can be configured for both high-level and low-level sensing. The switch is activated or deactivated based on the position of the float relative to the setpoints.

Q. What is the advantage of using float level switches in pump control systems?

Ans: Float level switches help prevent overflows and dry running of pumps by activating them when the liquid level reaches a certain point and deactivating them when the level falls below another setpoint. This ensures efficient and safe pump operation.

Q. Are there maintenance considerations for float level switches?

Ans: Float level switches are generally low-maintenance. However, it's essential to regularly inspect them for any debris or buildup that could affect their operation. Mechanical switches may require more frequent checks for wear and tear.

Q. Can float level switches be used with corrosive liquids?

Ans: Yes, there are float level switches designed to withstand corrosive environments. These switches are typically constructed with materials that resist corrosion, ensuring reliable performance in harsh chemical or industrial settings.

Q. Can float level switches be integrated into automated control systems?

Ans: Yes, many modern float level switches come with electronic components that can be easily integrated into automated control systems. They can provide signals for PLCs (Programmable Logic Controllers) or other monitoring and control systems.

क्रय आवश्यकता विवरण दर्ज करें

Level Switch अन्य उत्पाद

“हम अंतरराष्ट्रीय बाजार से पूछताछ की उम्मीद कर रहे हैं”

और हम मध्य पूर्व देशों, अफ्रीकी देशों, दक्षिण पूर्व एशिया और उत्तरी अमेरिका जैसे देशों से और पूछताछ चाहते हैं।

और हम मध्य पूर्व देशों, अफ्रीकी देशों, दक्षिण पूर्व एशिया और उत्तरी अमेरिका जैसे देशों से और पूछताछ चाहते हैं।

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese