हमें कॉल करें

08045800958

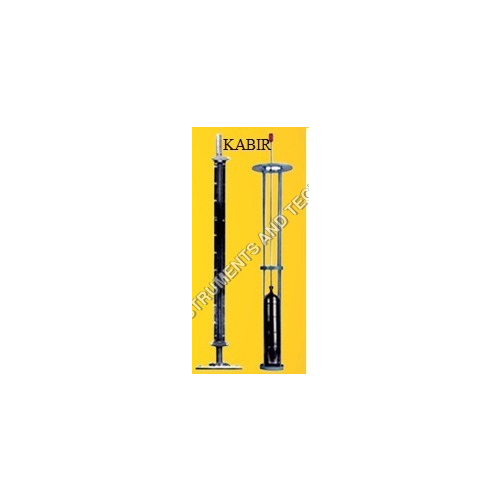

Top Mounted Magnetic Level Gauge

11700 आईएनआर/टुकड़ा

उत्पाद विवरण:

- डिसप्ले एनॉलॉग डिजिटल

- प्रॉडक्ट टाइप शीर्ष पर स्थापित चुंबकीय स्तर गेज

- एप्लीकेशन रासायनिक उद्योग

- Click to view more

X

टॉप माउंटेड मैग्नेटिक लेवल गेज मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

- टुकड़ा/टुकड़े

टॉप माउंटेड मैग्नेटिक लेवल गेज उत्पाद की विशेषताएं

- शीर्ष पर स्थापित चुंबकीय स्तर गेज

- रासायनिक उद्योग

- एनॉलॉग डिजिटल

टॉप माउंटेड मैग्नेटिक लेवल गेज व्यापार सूचना

- कैश इन एडवांस (CID)

- 01 हफ़्ता

- ऑल इंडिया

उत्पाद विवरण

A magnetic level gauge is a type of level measurement device used to determine the level of a liquid inside a vessel or tank. It operates based on the principles of magnetism.

Product details

| Accuracy | 10-15 mm |

| Measurement range | 20015000 mm |

| Country of Origin | Made in India |

| Usage | Industrial |

| Model Name/Number | Top Mounted Magnetic Level Indicator |

| Brand | kabir |

The basic components of a magnetic level gauge include:

1. Float: The float is a buoyant object that moves up and down with the liquid level. It is typically constructed with a magnetic element inside.

2. Magnetic Coupling: The float inside the tank is connected to an external indicator via a magnetic coupling. As the float moves with the liquid level, the magnetic field changes.

3. Indicator or Transmitter: This component is located outside the tank and is connected to the magnetic coupling. It measures the changes in the magnetic field and translates them into a visual indication or an electronic signal representing the liquid level.

4. Scale or Display: In some cases, there is a scale or display unit to provide a direct visual indication of the liquid level. For electronic systems, the signal may be sent to a control system or a display panel.

The principle of operation is simple:

1. When the liquid level in the tank rises or falls, the float moves with it.

2. The magnetic field within the float changes accordingly.

3. This change in the magnetic field is detected by the external indicator or transmitter.

4. The indicator then provides a visual representation or an electronic signal indicating the current level of the liquid.

Advantages of magnetic level gauges include their reliability, simplicity, and the fact that they are well-suited for corrosive or hazardous environments where direct contact with the liquid is not desirable.

Applications of Magnetic Level Gauge:

1. Chemical Processing Plants: Magnetic level gauges are often used in chemical plants to monitor the levels of corrosive or hazardous liquids in tanks. Their non-contact design is suitable for corrosive environments.

2. Petrochemical Industry: Tanks containing various liquids in the petrochemical sector, such as oil, gasoline, or other hydrocarbons, can be monitored using magnetic level gauges. The robust and durable nature of these gauges makes them suitable for harsh conditions.

3. Power Plants: Magnetic level gauges are employed in power plants to measure water levels in steam drums or other liquid storage tanks. Accurate level measurement is critical for maintaining the proper functioning of power generation systems.

4. Food and Beverage Industry: Tanks storing liquids in the food and beverage industry, such as dairy or brewing processes, often use magnetic level gauges. The non-contaminating and hygienic design is advantageous in these applications.

5. Water Treatment Plants: Magnetic level gauges are used in water treatment facilities to monitor levels in various tanks, ensuring efficient and controlled processes for water purification and distribution.

6. Oil and Gas Industry: Magnetic level gauges are suitable for monitoring liquid levels in storage tanks, separators, and other vessels in the oil and gas industry. They are particularly useful in environments with harsh weather conditions.

7. Marine and Shipbuilding: Magnetic level gauges are utilized in marine applications, such as monitoring fuel levels in storage tanks on ships. Their reliability and ability to withstand challenging marine environments make them suitable for such applications.

8. Pharmaceutical Industry: In pharmaceutical manufacturing, where precision and hygiene are essential, magnetic level gauges can be used to measure liquid levels in tanks containing various pharmaceutical substances.

9. Wastewater Treatment: Magnetic level gauges are employed in wastewater treatment plants to monitor liquid levels in different stages of the treatment process. The corrosion-resistant design is beneficial in the presence of various chemicals.

10. Aerospace Industry: In aerospace applications, such as rocket fuel storage, magnetic level gauges can be utilized to provide accurate level measurements for critical liquids.

Magnetic Level Gauge FAQ:

Q. How does a magnetic level gauge work?

Ans: A magnetic level gauge operates based on the principles of magnetism. It consists of a float with a magnetic element inside that moves up and down with the liquid level. The magnetic field changes as the float moves, and an external indicator or transmitter detects these changes to provide a visual or electronic indication of the liquid level.

Q. What are the advantages of using magnetic level gauges?

Ans: Advantages include reliability, simplicity, and suitability for corrosive or hazardous environments. They are non-contact devices, reducing the risk of contamination, and are often more durable than some alternative level measurement methods.

Q. In what industries are magnetic level gauges commonly used?

Ans: Magnetic level gauges find applications in various industries, including chemical processing, petrochemical, power generation, food and beverage, water treatment, oil and gas, marine, pharmaceutical, wastewater treatment, and aerospace.

Q. Can magnetic level gauges handle corrosive liquids?

Ans: Yes, magnetic level gauges are well-suited for corrosive liquids. The float inside the tank is typically made of materials resistant to corrosion, and the non-contact nature of the measurement reduces the risk of the gauge being affected by corrosive substances.

Q. Are magnetic level gauges suitable for high-pressure applications?

Ans: Magnetic level gauges can be designed to withstand high-pressure conditions. Manufacturers often provide specifications regarding the pressure ratings of their magnetic level gauge models, and special considerations may be taken for high-pressure applications.

Q. What is the maintenance requirement for magnetic level gauges?

Ans: Magnetic level gauges generally have low maintenance requirements. Periodic checks for proper functioning, cleaning of external components, and inspection for any damage are typical maintenance tasks. However, specific maintenance procedures may vary among manufacturers.

Q. Can magnetic level gauges be used for both point level and continuous level measurement?

Ans: Magnetic level gauges are more commonly used for continuous level measurement. However, some designs and installations can provide an indication of point level by using the presence or absence of the magnetic float at a specific location.

Q. Are there variations in magnetic level gauge designs?

Ans: Yes, there can be variations in design among different manufacturers and models. Some may incorporate additional features such as bypass chambers, multiple magnetic flags for redundant measurements, or electronic transmitters for remote monitoring.

Q. Can magnetic level gauges be used in extreme temperature conditions?

Ans: Magnetic level gauges can be designed to handle a wide range of temperatures. Special materials and insulation may be used to ensure the gauge's functionality in extreme heat or cold conditions.

Q. How accurate are magnetic level gauges?

Ans: The accuracy of a magnetic level gauge depends on various factors, including the design, installation, and the specific application. In general, magnetic level gauges can provide high accuracy in measuring liquid levels.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

स्तर सूचक अन्य उत्पाद

“हम अंतरराष्ट्रीय बाजार से पूछताछ की उम्मीद कर रहे हैं”

और हम मध्य पूर्व देशों, अफ्रीकी देशों, दक्षिण पूर्व एशिया और उत्तरी अमेरिका जैसे देशों से और पूछताछ चाहते हैं।

और हम मध्य पूर्व देशों, अफ्रीकी देशों, दक्षिण पूर्व एशिया और उत्तरी अमेरिका जैसे देशों से और पूछताछ चाहते हैं।

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें